No worries. Let me send you a copy so you can read it when it’s convenient for you. Just let me know where to send it (takes 5 seconds):

A great deal of product ideas has held back an awful lot of inexperienced entrepreneurs because they have no idea how to manufacture a product, or how to find a manufacturer to make their product happen. Putting good product ideas on the back burner is like throwing away a possible million-dollar opportunity that nobody in the business can afford to make.

It is what this comprehensive beginner’s guide is for–to help new entrepreneurs turn their ideas into tangible products and bring them to market. In the succeeding sections, you will get to learn more about the following:

Later in the article, we will also walk you through the steps on how to manufacture a product, including:

To get you started, here are some common manufacturing terms you will meet along the way.

Product manufacturing, or simply manufacturing, is the production of goods out of raw materials on a large scale. Finished goods or final/end products may be sold to other manufacturers for the production of more complex products, or be sold to wholesalers, retailers, or end users and consumers.

The product manufacturing process begins with a product design and specifications from which the product is made.

Note: If you want to explore the ground rules on how to manufacture a product, or what is known in the industry as new product introduction, we will dive deeper into this topic in Chapter #2.

Outsource manufacturing is the transfer of manufacturing and related support functions to third-party business entities, whether these third parties are onshore/domestic or offshore/overseas. Primarily, cost reduction and cost-saving drive companies to hire third parties.

Note: If you want to get to know more about the advantages and disadvantages of in-house manufacturing and outsource manufacturing, you will learn them in Chapter #3.

Contract manufacturing is a form of outsourcing where a manufacturer contracts with a purchasing company to do the production of product components or ready-to-use end products.

Contract manufacturing companies that handle packaging operations are called copackers or contract packagers. Contract manufacturing companies that work for another manufacturer are called subcontractors.

In the contract manufacturing business model, a purchasing company approaches different contract manufacturing companies to produce products for them, either with a product design or formula at hand or based on the contract manufacturer’s design. Contract manufacturing companies will quote the parts based on the cost of processes, labor, tooling, and raw materials.

After a purchasing company decides which contract manufacturer to partner with, the contract manufacturer will then produce and/or ship the components or end products either directly to end consumers or to the purchasing company (for assembly, packaging, etc.)

Contract manufacturing is used by various industries such as electronics, semiconductor, textiles, food, energy, personal care, and automotive, among many others. Over the years, contract manufacturing as a business model has proven to be an unfailing strategy mainly for cost reduction, from tax liabilities to labor.

Contract manufacturing done within a country is called domestic outsourcing/contract manufacturing. When a company outsources manufacturing of a product outside a country, it becomes offshoring or offshore/overseas contract manufacturing.

Note: You will learn more about the advantages and disadvantages of domestic contract manufacturing and overseas contract manufacturing in Chapter #4.

We have seen companies–big and small–introduce new products or fresh models of existing products in trade fairs year after year, from smartphones to laptops to virtual reality headsets and automobiles. What most people often do not realize is the rigorous process these products went through before they come to life. Behind the success of a product is the implementation of new product introduction.

What is a new product introduction?

New product introduction is used by contract manufacturing companies when getting started with a new product. A new product introduction process consists of various undertakings in stages, from the concept creation up to the manufacturing of the final product. The final product could be new or an iteration of an existing product and tangible (smartphones, laptops, etc.) or intangible (software as a service, product as a service, etc.).

New production introduction is often used interchangeably with new product development (NPD). Both NPI and NPD are part of the process of materializing a product or service from conceptualization to market. Most notably, the pre-release aspects are referred to as new product development, while the release to manufacturing and market aspects are referred to as new product introduction.

There are no exact same sets of steps as to how an NPI process should go as it all depends from organization to organization. But one thing is for sure to make the entire NPI process hit the mark is the cooperation and active support of the key decision-makers in an organization.

There are no exact same sets of steps as to how an NPI process should go as it all depends from organization to organization. But one thing is for sure to make the entire NPI process hit the mark is the cooperation and active support of the key decision-makers in an organization.

Why is it necessary to implement an NPI?

An organization that develops and implements a solid NPI process positions itself closer to the success of a product. One obvious advantage is cost reduction; every decision in the product development process affects the cost be it brought by repeated revisions, validation testing, and design changes.

Cutting down the frequency of revisions, validation testing, and design changes could mean more time to market the product or an early generation of revenue. An NPI process also helps determine whether a product concept is marketable and/or saleable.

If a purchasing company enters an agreement with any contract manufacturing companies, both camps work hand in hand to make the final product happen. For new products, an NPI is in a way an investment on the contract manufacturing companies since profit has yet to be made. Through the NPI process, the success/failure of a product is anticipated.

Of course, there are other factors necessary to bring out the success potential of a product, such as timing and cost. We will dwell more on that in later sections of this article.

In this chapter, we will walk you through the general phases of a new product introduction process, including the requirements, tools, and documents necessary.

All production starts with conceptualization where you lay the groundwork for all subsequent processes. At this stage, ideas for a product are born, whether the product is a totally new one or an iteration of an existing product.

Conceptualization highly depends on research to ensure that the product concept is marketable and/or saleable. Market research is hyper-critical for a product to become profitable.

Conceptualization highly depends on research to ensure that the product concept is marketable and/or saleable. Market research is hyper-critical for a product to become profitable.

What is it for? Who would use it? Is there a demand for it? How will it solve a problem? Is there an existing product of similar kind? How will yours be different?

Your research should answer all these basic questions about your product concept before moving forward with the next steps.

A product design concept presents a potential product’s requirements with a full description of the features and functions, taking into account the voice of the consumer (VOC). All information gathered will be converted to design specifications, which will be incorporated into one or more design concepts. A project charter shall be made hereafter.

A project charter may include background information, objectives, scope, key deliverables and dates, budget, stakeholders and sponsors, potential risks, concerns, and assumptions, among others.

An initial business case identifies the market or customer and the competition. Within the business case are benefit costs analysis (BCA), cost sensitivity analysis, cost risk analysis, and cost contingency analysis. A business case also contains clear definitions of success and failure, which you can refer to in the following stages of the project.

Through a feasibility study, the management is able to assess the project’s potential for success. Here the project team evaluates the product design concepts and decides on the design that best meets the predetermined requirements. This stage may include a boundary diagram, preliminary design concept, process flow diagram, and bill of material (BOM), among others.

Once all these are fulfilled, the project team or the management can decide whether or not the project or proposed product design should push through, be redesigned, or forgo altogether.

The product design and development stage is where you use the outputs from the conceptualization and research phase. Here you will improve and/or advance the product design features and specifications, including dimensions and materials. An extensive review of the chosen product design helps in assessing its robustness, customer suitability, and performance requirements.

In addition, the production process needs to be reviewed as well, including the equipment, space requirements, preliminary process mapping, and location. Where necessary, you will tap other business units to help in supplier selection, material forecasting, and other operational concerns.

In the product design and development stage, you should be able to create outputs like:

A bill of materials, also known as product structure, is a list of raw materials, assemblies, components, parts, and the quantities of each necessary to manufacture an end product.

It serves as a reference between manufacturing partners (contract manufacturing companies and their customers) or units in a single manufacturing plant. Often, it comes with a production order for reservations of in-stock components or requisitions of out-of-stock components.

Design for manufacturing is a technique used to simplify, optimize, and refine a product design. Through this process, the manufacturing team is able to assess how easy or difficult it is to manufacture the design.

It is an important process to anticipate issues and know how to avoid them early on, thus reducing the overall production cost. DFM may include the selection and review of raw materials, dimensional requirements, and packaging.

During the stage review, the project team sets forth an updated information about the design, project timeline, risk assessments, and an updated business plan or report of financial status. From here, the management team determines whether they should proceed to the next stage or test plan further.

The prototyping stage is where you produce and test a batch of product samples commonly known as a prototype. A prototype is used to review the actual product design, find and resolve defects or problems, and/or implement necessary design changes. Through prototyping, the manufacturing team would be certain that the specifications are real and the product is working.

Once the first batch of prototypes is tested, the manufacturer will then proceed to the second build called design verification, which is intended to be close to the final production unit. Oftentimes, 3D printed plastic and other low volume mechanicals are used in design verification to mimic the look and feel of the end product before spending on tooling.

Product validation is the final build in the new product introduction process. In essence, product validation is a dry run of full-scale production where labels, shipping boxes, etc. are included in the analysis and testing.

In the prototyping stage, you should be able to have outputs like:

During the stage review, the project team should review the outputs with the management team. If approved, the process proceeds to the final stage of the new product introduction process.

As soon as product validation gets the green signal, full-scale production commences where the final prototype of the end product is being mass-produced.

If you are working with a contract manufacturer, it usually starts with a request for an assembly package, which may include the following:

These are necessary for the contract manufacturer to estimate the cost of product manufacturing as well as a requisition for unavailable components.

The product manufacturing phase is fine-tuned and validated through the prototypes and capability studies. Additionally, process documentation and quality controls are developed and implemented at this point.

Full-scale production may include the development of manuals, price list, catalog and quote tool, process work instructions and standard work, approval of supplier PPAP submissions, internal training of associates, external training of sales, dealers, etc., production control plans, process capability studies or statistical process control, packaging evaluations, and final safety/regulatory review.

These are just the fundamentals on how to manufacture a product. Keep them in mind as we move towards the more actionable aspects on how to manufacture a product.

But before that, we will walk you through the advantages and disadvantages of in-house manufacturing and outsource manufacturing in the following chapter.

Product manufacturing is not just about completion. Product manufacturing puts consumers’ interest to the core for a product to take off.

Product manufacturing is not just about completion. Product manufacturing puts consumers’ interest to the core for a product to take off.

Behind the success of every product is the product manufacturing process that shapes it up before hitting the shelves. Is outsource manufacturing really more beneficial than in-house manufacturing? Or does it matter at all?

Choosing between in-house manufacturing and outsource manufacturing to contract manufacturing companies requires both a thoughtful and economic decision. Above all, the decision should be strategic at any cost.

In this chapter, we will explore the advantages and disadvantages of both in-house manufacturing and outsource manufacturing to a contract manufacturer so that you can make a sound decision that is right up your business’s alley.

In-house manufacturing conducts manufacturing and/or production activities within a company using its own internal resources, assets, and employees. Most developed countries choose to outsource manufacturing to a contract manufacturer for a lot of reasons, including cost reduction.

Despite this trend, much has been written about bringing manufacturing back in-house. And as always, the main argument centers on protecting the manufacturing jobs of a country.

Product manufacturing in-house is a great way to refine your process and technology, keep tabs of your expenses, improve quality, and ferret out new applications, among other things.

Having a full, unabated control over your manufacturing and production process from start to finish is one of the primary advantages of in-house manufacturing. This may include control over the quality, product design, raw materials, process optimizations, packaging, and delivery.

As a result of your control over the process, it gives you the opportunity to become more flexible and adaptable as and when you see fit. In particular, this is extra helpful if you are in an industry that changes pretty quickly, or if you have a product that is very responsive to consumer-led changes. In-house manufacturing makes changes between design, engineering, product development, and production a lot easier to process.

Without middlemen or contract manufacturing companies, it is much easier to communicate any specific instructions. What this means for managers or supervisors is that reaching out to all departments first hand can be done immediately and seamlessly.

For companies with trade secrets, the manufacturing process can never be negotiable. Keeping manufacturing in-house not only protects and preserves the company’s unique way of production or technology but also competitive advantage. Outsourcing product manufacturing to a contract manufacturer puts your advantage in jeopardy by all means.

Although there are laws protecting your company’s intellectual and physical properties, with the presence of an NDA with your contract manufacturer, as soon as your production leaves your home turf, you cannot always guarantee that no compromise will happen later down the line.

Intellectual property is a major consideration before choosing between a domestic contract manufacturer and an overseas contract manufacturer. If production costs are not an issue, it is always necessary to keep product manufacturing in-house. You do not want someone to reverse-engineer your one in a million product design, do you?

Labor cost is the primary reason why companies in more developed countries would rather choose a contract manufacturer than doing it in-house. Apple, IBM, and Cisco Systems, among many others, have partnered with contract manufacturing companies in China and India to bring their award-winning products to life. In-house manufacturing means you will pay for salaries, payroll taxes, and all benefits that your workers are entitled to.

In-house manufacturing also means you will buy your equipment, rent your own warehouse or factory, and foot all maintenance and utility costs. If you are a new brand, you are likely to spend on your overhead expenses much more than what you can earn in the first couple of years.

It is not ideal for small budding companies to manufacture their products in-house if they started out with low demand. They have to make sales, yet they need to pay taxes, salaries, utilities, and other expenses to operate. If they do not make sales or a steady stream of revenues, the company is going to fail and die on its feet.

In-house manufacturing entails a lot of legal responsibilities to take care of, including waste management. It is a critical matter that many new companies have to look into first before venturing into in-house manufacturing.

If you have all the resources, you can have your own systems, processes, and the right equipment to deal with it. Otherwise, contract manufacturing companies are a great option.

Outsource manufacturing is the process of hiring people outside of a company to build or assemble a product. Cost reduction is the primary benefit when outsourcing parts of the production line to a contract manufacturer, making outsource manufacturing great for your margins and bottom line.

However, outsourcing product manufacturing to contract manufacturing companies also comes with disadvantages.

Labor cost is the most common reason why many companies choose to outsource manufacturing to a contract manufacturer, especially if it is done overseas. A lot of contract manufacturing companies rent out their factories and its workers for you to maintain and manufacture your product.

In most companies, if not all, labor takes up the biggest chunk of a company’s budget. Outsourcing product manufacturing to contract manufacturing companies minimizes your operating expenses since you are not directly paying salaries, payroll taxes, and benefits of the factory workers. Some contract manufacturing companies offer services beyond production, such as storage facility and shipping, that you can use to your advantage.

Companies in the product manufacturing business, especially in China and other Asian countries, have technically and highly skilled factory workers who are willing to work for a fraction of salaries in the United States.

For contract manufacturing companies outside the United States, they have fewer regulations in relation to labor conditions, right-to-work laws, use and disposal of materials, and other aspects of manufacturing that jack up the production costs in more developed countries and regulated countries.

Tapping the resources of contract manufacturing companies not only reduces labor costs but a slew of other maintenance and utility costs and taxes as well. These might include real estate, gas, electricity and water, insurance, building, security, property taxes, and other operating and overhead costs due to indirect labor.

If you are running a mid-sized business or any complex organization, outsourcing product manufacturing to contract manufacturing companies allows the management to concentrate on their core competencies and objectives or on sales and marketing.

Reducing your expenses could mean two things for your company. One, you can use your savings to augment your operating capital, even if your sales remain the same. Or, it could be spent on marketing, research and development, salary increase, debt payment, and other aspects that can help your bottom line.

Two, you may opt for lower price levels or maintain it as it is with your reduction by outsourcing product manufacturing to a contract manufacturer. As a result, you can increase your market share and your sales, which is good your profit margins.

Outsourcing product manufacturing to contract manufacturing companies means you are entrusting your product from the ground up. In case your contract manufacturer is offshore, quality control might be uncertain, especially if you have no idea of your contract manufacturer’s reputation.

Losing control over the quality product is not good for your branding and reputation in the grand scheme of things, most especially if faulty goods reach the hands of your customers. There are remedies to solve this specific problem though.

By hiring an agent or an on-site manager to oversee the manufacturing process abroad and perform regular quality checks, you make someone responsible for ensuring the utmost quality you are looking for in your product.

Communication is another issue you may face when outsourcing product manufacturing to a contract manufacturer, especially if the contract manufacturer is offshore. Time zone differences and language barrier are two common downsides here.

With time zone differences, it goes without saying that response time would be an issue between a contract manufacturer and a purchasing company who are halfway around the world distant from each other.

But just as previously suggested, hiring an agent can help you ease the operations for you. Say you want to hire an agent in China, there are lots of English-speaking agents nowadays so that should not be a deal-breaker. As your agent, they are obliged to report to you and respond promptly.

It is no longer a secret these days that even the biggest companies in the world are outsourcing their product manufacturing to contract manufacturing companies, mostly in China, Taiwan, India, Pakistan, Bangladesh, and other Asian countries. But there is still a stigma that comes with it, which many public relations people and marketers use against competitors who hire contract manufacturers abroad.

Outsourcing product manufacturing to contract manufacturing companies might be cost-effective labor-wise, it is often not the case if a company does not make prior arrangements regarding storage and shipping very well. Logistics can be a great expense if you will do it on your own.

Depending on your manufacturing budget, you can agree with a contract manufacturer to take care of the storage, shipping, and even distribution of the product. In the long run, it is much wiser to include warehousing and shipping of your product in your contract.

Based on the aforementioned benefits of contract manufacturing, whether it is domestic or offshore, cost reduction is the prime motivator why businesses should start outsourcing product manufacturing.

If you are new in the business, it makes much more sense to look for the right contract manufacturing companies to save you an awful lot of money. If you are in the business for quite some time, there is room for you to lower your product cost or augment your marketing campaign, which could skyrocket your sales exponentially.

Nevertheless, it still pays to be logical about it. If the security of your technology, production processes, or intellectual property is on the line, staying in-house should be non-negotiable.

You can explore more of the advantages and disadvantages

of domestic contract manufacturing and overseas contract

manufacturing in the next chapter.

In the product manufacturing industry, outsourcing the work to contract manufacturing companies can reduce the production costs. Outsourcing product manufacturing to overseas contract manufacturing companies, however, can drastically make cutbacks in production costs.

In the product manufacturing industry, outsourcing the work to contract manufacturing companies can reduce the production costs. Outsourcing product manufacturing to overseas contract manufacturing companies, however, can drastically make cutbacks in production costs.

It is the same reason why a lot of companies in more developed countries outsource manufacturing to overseas contract manufacturing companies. To say the least, overseas contract manufacturing is a lot more common than domestic contract manufacturing. Even so, it does not imply that overseas contract manufacturing is far superior to domestic contract manufacturing in all ways.

In the last two decades, more and more American companies have been outsourcing parts of their products or their final products to contract manufacturing companies in China.

Recently, there have been discussions over bringing manufacturing back to the United States due to a variety of reasons, including the rising labor costs, quality issues, and other concerns. And the series of trade wars between Beijing and Washington is rubbing salt in the wound.

Is it really time to bring product manufacturing back to the American shores? When choosing how to manufacture a product, a bunch of factors comes into play. Let’s weigh the advantages and disadvantages of domestic contract manufacturing against overseas or offshore contract manufacturing.

In the last two decades, production costs have been predominantly the main reason why companies in more developed countries choose to outsource manufacturing to offshore contract manufacturing companies.

Despite the increase in average workers’ wage in countries like China and India, getting an overseas contract manufacturer remains more cost-effective than domestic contract manufacturer, regardless if we take into account the other benefits of domestic contract manufacturing. Raw material cost is only secondary to labor cost in any way.

For companies whose products have price as their competitive advantage, outsourcing product manufacturing to offshore contract manufacturing companies would make a lot more sense. Unfortunately, domestic contract manufacturers in more developed countries cannot compete with unit costs overseas.

In terms of quality control, domestic contract manufacturing companies give you an advantage to a large extent. A factory that is just a few miles away from you does not only allow you to personally perform quality checks on a regular basis but saves you the cost of hiring a sourcing agent, flying abroad, or sending someone from your company overseas.

For companies outsourcing products to contract manufacturing companies abroad in high quantities, quality assurance is an important thing to consider as well. Without having anyone from your company to oversee production overseas, it somehow increases the chances of your customers to receive defective goods.

Of course, you want your products to do exactly what it says on the tin can. The practical way to make sure your offshore contract manufacturer upholds the quality you want for your product is to hire a reliable sourcing agent or send a representative from your company abroad, depending on the needs and scale of your business.

Lead time is a crucial aspect of the conceptualization-to-production process that domestic contract manufacturers have the advantage. In this fast-paced age, the earlier you send a product to the market and address consumer questions and concerns means the world to companies. It can make or break a sale.

Most products run on a 30-50-day lead time, from factory to end product. Although, lead time varies from product to product.

Earlier in the NPI process, prototypes and sample products could be shipped back and forth for inspection and testing quite a few times. Having a domestic contract manufacturer means you are cutting down precious hours and days due to shipping.

However, this is not to say that offshore contract manufacturing companies have a terrible lead time. Outsourcing product manufacturing overseas would not be as successful as it is today if it is always the case. The key takeaway here is to choose a trustworthy overseas contract manufacturer who you think you can build a relationship with and can be sensitive with your timeline and targets as well.

Generally, domestic contract manufacturing companies have greater flexibility than overseas contract manufacturing companies.

Domestic contract manufacturing companies can take in smaller production runs with ease. Offshore contract manufacturing companies may also be willing to accommodate orders in low quantities, but this might come at the expense of shipping costs.

For just-in-time orders, domestic contract manufacturing is more beneficial than overseas contract manufacturing. In the case of returned defective items, the turnaround time for the goods to reach the overseas contract manufacturer and back to the buyer might take a bit longer.

Communication is a key element in the product manufacturing process that many new companies often overlook. Outsourcing manufacturing overseas, especially in Asia, does not only present problems like language barriers, a disparity of work ethics, and cultural differences as the main communication hurdles.

Poor communication skills–whether on your part or your contract manufacturer–can threaten a smooth production process. If you are doing business with Chinese contract manufacturers, it is recommended to come to the terms to your contract manufacturer, considering it is reasonable, of course.

How to avoid communication breakdown with your offshore contract manufacturer? Seek the help of a bilingual sourcing agent or company.

Importing products from abroad can be an awful lot of work. The transportation, delivery, and every single thing that happens in the shipping of products could be quite stressful if you deal all by yourself.

Customs regulations, taxes, and a variety of fees throughout the process can put you in an unpleasant situation. With this in mind, you have to make sure that production costs when outsourcing abroad should not drag your product down.

China has been consistently leading the world’s top manufacturing countries for so many years now. It is also the largest exporter of goods, way ahead of the United States. In the last few years, many cities in China have become significant production centers.

According to the latest report by the World Bank, China produced $4.566 trillion of industrial output in 2016, of which $2.342 trillion are exported goods, and continued to grow by 6.6 percent in September 2017.

According to the latest report by the World Bank, China produced $4.566 trillion of industrial output in 2016, of which $2.342 trillion are exported goods, and continued to grow by 6.6 percent in September 2017.

There is no stopping in sight for China from dominating the product manufacturing industry. Just as what industry experts believe in, China will continue the streak in the next couple of years as the go-to nation when it comes to product manufacturing, despite the fact that there are so many outsourcing destinations to choose from.

And you might be wondering: Why is China the best country to outsource manufacturing? We have a thousand points to show you, but we will condense them into three main reasons.

Labor cost is often the main reason that drives companies in more developed Western economies to outsource manufacturing in China. Chinese labor might no longer be as cheap as it used to be years ago, China’s pool of technically skilled workers maintains its competitive advantage in the product manufacturing landscape at a still inexpensive price.

Although there are many other outsourcing destinations that offer cheaper labor, China’s stable facilities and advanced technologies have also been its winning edge, still at relatively low production costs. In comparison with its product manufacturing counterparts in Asia, China can deal with common problems that directly affect the product manufacturing workflow, such as power interruptions and unstable supply lines, among many others.

Political stability is another important aspect that product manufacturing companies in China can be proud of. There are no other product manufacturing destinations in Asia that have a strong political stability as China. As long as national laws and government regulations are met, product manufacturing companies and their partners need not worry.

Outsourcing product manufacturing to contract manufacturing companies in China is not without some challenges. China may be the world’s biggest product manufacturing country, there are lots of things you must reckon before finally deciding to outsource product manufacturing in the country.

Most of these challenges, however, are not exclusive to Chinese contract manufacturing companies. Companies may face the same circumstances in other product manufacturing destinations.

The good news is, these hurdles can be preempted if you do your part. One way you can meet these challenges head-on is to wrap your head around the process on how to manufacture a product that we laid out earlier in Chapter #2.

The good news is, these hurdles can be preempted if you do your part. One way you can meet these challenges head-on is to wrap your head around the process on how to manufacture a product that we laid out earlier in Chapter #2.

By understanding the NPI process and how to manufacture a product and meeting all relevant outputs first, you get to anticipate and prevent the cost overruns and other bumps later down the line.

By becoming aware of the process, product manufacturing (and the supply chain in general) can run like a well-oiled machine. It is important to note that, in supply chain management, the succeeding links are highly dependent on the preceding links.

In this chapter, we will present to you the major problems that you may face if you decide to work with contract manufacturing companies in China. Of course, we will not leave you battling challenges out without some recommendations.

And finally, in the next chapter, you will learn all the ropes of contract manufacturing in China–how to find a manufacturer that is truly capable; how to manufacture a product with the right contract manufacturer; how to request a quotation from your supplier; generally how to deal with contract manufacturing companies in China.

While it sounds a little contradictory to what makes China the best product manufacturing destination, it is not. Let us explain why.

China is home to thousands of product manufacturing companies and millions of skilled factory workers. They know how to manufacture a product, of course. In spite of that, not all contract manufacturing companies in the country are dyed in the wool when it comes to quality control, prompt delivery, and customer service.

Many contract manufacturing companies in China have factories with fairly old equipment, processes, and workflows. And because of the pressure to lower production costs, some contract manufacturing companies would resort to substituting lower grade materials or assigning the product manufacturing process to a lower caliber factory where no quality control is done.

Failure to find the right contract manufacturer in China could mean less than expected service quality and even passing on the expected cost reduction or capital investment reduction.

In terms of quality control monitoring, you can leverage your ERP or any cloud-based business intelligence and analytics software to feed you with real-time or up-to-date feedback on your product before it reaches the consumers.

You might have perfectly ticked off your checklist in finding the right manufacturer in China, it is not always a guarantee that the contract manufacturer will do business with you. In most cases, contract manufacturing companies are more interested in the revenue they will get rather than the amount of business you can offer.

Contract manufacturing companies determine this through volume projection alongside your product specifications and bill of materials. Often, contract manufacturing companies would gladly consider compromising short-term revenue gains if they see that your product will let them enter a new market with strong growth potential.

The lack of interest in small-scale contracts is not always the case. When finding the right contract manufacturer for you, make sure your business’s scale is on a par or in proportion to the contract manufacturer’s. This way, you are likely to pique the contract manufacturer’s interest.

In the selection process, contract manufacturing companies would always present to you that they have the best support team to make your product design happen. While it is hard to determine how many clients contract manufacturing companies are attending to at the moment, it is often more than you think of.

In most instances, contract manufacturing companies manage multiple demand streams, so they are more likely to accept whatever projects that come their way as long as they make money off them. In which case, they might have to assign your project to another contract manufacturing team or factory, which has less experienced or competent personnel.

Small-scale product orders and bare minimum order quantity (MOQ) are usually an easy target to get assigned to another contract manufacturing team. The same holds true when the contract manufacturing companies accept new, larger customers.

Be critical with contract manufacturing companies who present the best support team to you. Knowing that they have the best contract manufacturing team is not enough to guarantee that your product design is in good hands.

To avoid these kinds of scenarios, it is also important to start building a relationship with potential contract manufacturing companies right off the bat by making a positive impression.

As the world’s biggest product manufacturing country, you can expect China to serve thousands of companies around the world. Product manufacturing delays is a common issue in China due in large part to the number of companies these contract manufacturing companies are serving.

Production delays are caused by a lot of reasons. A contract manufacturer could bump your order to give way to a larger client. Perhaps, a subcontractor failed to meet your contract manufacturer’s deadline, thereby affecting your timeline. Manufacturing errors are also possible. The list goes on.

These things, along with inconsistent service quality and communication issues, are inevitable and sometimes beyond your control. That is why it is ever so important to know the process how to manufacture a product and find the right contract manufacturer–one that suits your needs–and set boundaries and expectations first.

When it comes to environmental regulations, new companies who are looking to outsource manufacturing to a contract manufacturer in China might know that a contract manufacturer is responsible for the compliance to the requirements of the government. It is true, but it does not necessarily mean that the hiring company is free from responsibilities.

Many existing companies have been slapped by complaints and violations either due to the fact that their contract manufacturers do not meet the environmental requirements set by national laws or they themselves failed to comply with them.

Ignorance of environmental laws could result in a great trouble that could lead to your company’s closure. Pressuring your contract manufacturer to provide proper product documentation and comply with laws and regulations is not enough. Note that you are also liable when your contract manufacturer screws up.

If you become familiar with how to manufacture a product, you should be familiar with the post-production evaluation too.

Some brand owners and contract manufacturing companies are used to downplaying product evaluation, and they think they can get away with nasty consumer reviews. In fact, in the new product introduction process, this is the most neglected part.

There are so many contract manufacturing companies that do not take post-production assessment seriously. And it comes as no surprise to see the same bad product reviews over and over again.

Evaluating your production manufacturing allows you to know if the entire process is working or if there are holes in it. It allows you to identify areas of improvements and changes.

Most decisions to outsource product manufacturing to overseas contract manufacturing companies are fueled by the expectation of big labor cost savings. Considering the rising wages and other production expenses in developing countries in the last few years, labor savings have become a thing of the past in some way.

Companies that have failed to revisit their past outsourcing decisions today might be shocked to learn that a lot of things has changed since 10 or 20 years ago. For emerging companies, the opportunity of learning the trends and best practices of outsourcing product manufacturing presents itself.

Pricing surprises are the second most common cause of dispute between a client company and a contract manufacturing company. In most cases, the client company takes the demerit because they fail to read the fine print before sealing a deal.

Pricing surprises are the second most common cause of dispute between a client company and a contract manufacturing company. In most cases, the client company takes the demerit because they fail to read the fine print before sealing a deal.

As soon as the client company sees the bottom line pricing, the deal looks pretty good on the surface since there is a significant cost saving in sight. Little time is spent on getting a solid grasp of the unexpected costs, whether or not contained in the contract.

We are talking hidden costs of outsourcing product manufacturing, not only in China but wherever there is product manufacturing. These costs are “hidden” because they might not be clearly stated or agreed upon on paper.

These hidden costs are mostly opportunity costs that you lose due to oversight or the lack of nitpicking over minute details of the entire product manufacturing process. Note that these costs are difficult to calculate since they depend on factors like product type, purchase order, etc.

Often ignored at the outset of the process, inventory liabilities are a common cause of burned bridges between a client company and a contract manufacturing company when no party is willing to take responsibility for them. Inventory liabilities many a time is a repercussion of the client company’s failure to meet the forecasted demand against, say, actual sales.

Before signing any contract agreement, make sure to know and understand your liability profile and negotiate them as much as possible. Be clear with your contract manufacturer where your liabilities begins and ends. Will they be based on a purchase order, stocking level, forecast, etc.?

A lot of companies think after getting a quotation from contract manufacturing companies, the quoted price is final. While it may be true for the most part, the price of raw materials, oil, and other resources fluctuates over time. The currency exchange rate is another concern subject to fluctuation that you need to assess.

With all these fluctuations, a contract manufacturer might see it necessary to increase the price on your end. These fluctuations are beyond the bounds of your control, but what you can do is to prepare for foreseeable events like this.

In the supply chain involving outsourced product manufacturing overseas, it is imperative to learn what Incoterms are. Incoterms, or International Commercial Terms, are a set of three-letter codes used as the standards of international shipping.

Incoterms guide the client company and the contract manufacturer overseas regarding their responsibilities over the shipment of goods. These codes dictate where your responsibilities as a purchaser begin and where the responsibilities of a contract manufacturer end.

Incoterms guide the client company and the contract manufacturer overseas regarding their responsibilities over the shipment of goods. These codes dictate where your responsibilities as a purchaser begin and where the responsibilities of a contract manufacturer end.

Without knowledge about these terms, you are likely to shoulder additional expenses in warehousing and transportation charges or penalties. Add to those the various customs fees.

Indirect costs are not your typical overhead expenses, which can be both fixed or variable. Indirect costs are not normally stated in the contract, but contract manufacturing companies offset these costs through other means.

They are not illegal to any extent. You as a client company should be wise enough to calculate how much your contract manufacturer is imposing on you based on your BOM, etc. In some cases, these have markups to make up for the contract manufacturer’s other production and maintenance expenses.

Know that beyond the cost of raw materials, labor, transportation, etc., contract manufacturing companies have to maintain their factories, facilities, equipment, floor space, etc. and hire support services of IT, handling, record-keeping, inspection, accounting, and other personnel.

These costs are often associated with out-of-the-box products. Warranties for faulty products, including repairs and replacements, can be a huge blow to your bottom line. In most cases, you as a brand owner will have to shoulder the full or a fraction of the shipping, repair, and replacement costs.

Customer returns or salvaged goods are another pain in the neck to brand owners. You are not only losing sales for these, but you are most likely going to pay for the shipping costs as well.

Lastly, for unsold goods and items that do not meet your quality standards, you might be forced to sell them at a discount. Otherwise, you might not be able to recover the costs of making these products.

These events are inevitable. One way to decrease your returns and replacements is in quality control, which something you may or may not have depending on the terms of your agreement with your contract manufacturer.

After learning how to manufacture a product and the ropes of product manufacturing, we are finally down to the final chapter where we will break down the steps on how to find a manufacturer, how to choose a contract manufacturer, and more.

You have a product idea, but you have no idea how to manufacture a product. That is fine; every new company that intends to establish its own brand has been there.

You have a product idea, but you have no idea how to manufacture a product. That is fine; every new company that intends to establish its own brand has been there.

Hold it right there. We know how eager you are to learn how to manufacture a product, distribute it, and make money off it

In this chapter, you will learn a ton of things that will be instrumental in a product’s success. These include the process on how to find a manufacturer, how to choose a contract manufacturer or supplier in China, how to outsource manufacturing in China, how to calculate manufacturing overhead, how to request a quotation from suppliers or contract manufacturing companies, how to ensure product quality and lead time, and how to protect your intellectual property from your contract partner.

How to find a manufacturer is one of the most important steps in your business. But after reading all the pros and cons of outsourcing product manufacturing to an overseas contract manufacturer, you might have no idea right now how to find a manufacturer in China to get your product off the ground.

There are a couple of proven and tested methods on how to find a manufacturer in China. An online directory is one of them.

Due to the demand in the e-commerce business today, a lot of online directories have sprouted boasting to have “direct” connections with product manufacturing companies in China. You want to avoid them because more often than not, most connections of these online directories are just trading companies and distributors.

Although, not all online directories are bad. As a brand owner, you would want to reach out directly to your contract manufacturer. Not only it is cost-effective since no middlemen are involved, but it also gives you a direct and clear line of communication with the manufacturer.

So, how to find a manufacturer in China via online directories without getting scammed? In this chapter, we will discuss the most common and effective ways on how to find a manufacturer in China.

Alibaba.com is the world’s largest e-commerce platform where you can find millions of products and thousands of suppliers from China. Alibaba has become the most comprehensive online directory of manufacturers, traders, and wholesalers, connecting them to all buyers from around the world.

Is Alibaba safe to use?

Alibaba is a marketplace. Like any other real-life marketplaces, there are bad and dishonest ones lurking around. Nevertheless, Alibaba is safe to use if you know what you are doing and how to find a manufacturer correctly.

When searching for product suppliers on Alibaba, you can filter the search results according to:

Your goal is to get the safest suppliers to appear in your search results, so you tick all three of them. Let us explain how these filters work.

Trade Assurance suppliers accommodate an escrow, which means a third party holds your payment to the supplier until the conditions in your transactions are fulfilled like the goods are delivered to you correctly. This is the most secure of them all.

Gold Supplier is an exclusive membership to select suppliers on Alibaba. They should earn it. One of their perks is visibility on the platform, meaning their products are a priority for exposure.

But not all Gold Suppliers are good and honest. So when choosing a Good Supplier, be sure to note how many years have they been rated as such. The longer, the better.

Assessed Supplier is the most important filter. It basically means that a third party has inspected the supplier and its facilities.

Assessed Suppliers have often solid company profiles, robust sales performance, and active participation in trade fairs.

Above all, you ought to validate all these things for yourself. You still need to check company profile and read reviews and feedbacks on forums before dealing with a prospective supplier from China.

In terms of transaction details, make sure to take note of the MOQ, price per unit, and payment terms of a supplier for a certain product. As much as possible, avoid middlemen or traders.

Owned by Alibaba Group, AliExpress is the retail version of Alibaba.com. It operates at the consumer level where you can purchase products in lower quantities at factory prices.

AliExpress does not have a vast pool of manufacturers as Alibaba. Instead, it teems with traders and smaller distributors. They might know how to manufacture a product, but they are not the right people if you are looking to produce goods in large quantities.

If you are a small business or someone who wants to venture into the e-commerce business without having to deal with MOQ requirements, AliExpress is a great alternative.

There is no other classic way how to find a manufacturer and be sure how to find a manufacturer correctly than trade fairs. Chinese trade shows are becoming a force to reckon with as the economy and technology levels are boosted.

Thousands of businessmen from around the world show up at trade shows in China in the hopes to buy or sell products and products that have an exponential growth potential.

If you want to attend trade shows in China, you should be looking at the top events happening around the country, including the Canton Fair (China Import and Export Fair), China Yiwu International Commodities Fair, Bauma Fair, and Shanghai Import and Export Commodity Fair.

If you want to attend trade shows in China, you should be looking at the top events happening around the country, including the Canton Fair (China Import and Export Fair), China Yiwu International Commodities Fair, Bauma Fair, and Shanghai Import and Export Commodity Fair.

The Canton Fair’s spring events usually happen from April to May, while the fall season events happen from October to November.

After learning how to manufacture a product and how to find a manufacturer, choosing the right contract manufacturer should be your next agenda. You might know how to manufacture a product and how to find a manufacturer, looking for a contract manufacturer to partner with can take a lot of time and effort on your part.

Like any other facets of a business, outsourcing the product manufacturing work is more than just an economic decision. It is a strategic decision that puts the future of your product and your brand on the line.

Gone are the days of cost reduction and cost savings as the main criteria when choosing the right contract manufacturer. Thousands of product manufacturing companies offer the same categories of products. You must select the manufacturer that will best serve your interest, your budget, and your needs without sacrificing quality and timeline.

Before sealing a deal, make sure to perform background checks. But the question now is: what should your criteria be in the selection of a partner contract manufacturer? Here is how to choose a contract manufacturer or supplier in China.

Your presence and visibility on the production floor is something you need to give up when outsourcing abroad. This makes communication one of the top priorities when looking for a contract manufacturer.

You cannot guarantee how contract manufacturing companies muddle through communication with foreign clients. Getting a contract manufacturer’s email and phone number is not enough.

The best thing you can do to ensure a contract manufacturer responds to your queries is to ask for their customer service hotline. These days, many Chinese contract manufacturing companies have English speaking staff that supports their business.

As a client company, you are entitled to access any information relating to your product, including real-time storage temperature date, shipment confirmation, assay results, etc.

In the selection process, one good way to discern whether or not contract manufacturing companies are likely to have a good, open line of communication and customer service is if they will highlight or encourage you to request status reports, quality reports, and real-time updates.

A minimum order quantity, or the lowest amount of stock that product manufacturing companies are willing to sell, is a huge setback among small-scale companies, particularly in the dropshipping business. Usually, high-ticket products have lower MOQ, while low-ticket products have higher MOQ.

Depending on which product you are going to outsource, look for contract manufacturing companies that have lower MOQ. But do not be fixated on low MOQ alone. If you are negotiating MOQ, note that some product manufacturing companies would sometimes charge buyers at a higher price per piece for smaller purchase orders.

Most Chinese product manufacturing companies operate on razor-thin profit margins, usually as low as 3-4 percent. For products with low-profit margins, product manufacturing companies have to produce them in large quantities in order for them to break even. Otherwise, they will have to price the products higher.

Most Chinese product manufacturing companies operate on razor-thin profit margins, usually as low as 3-4 percent. For products with low-profit margins, product manufacturing companies have to produce them in large quantities in order for them to break even. Otherwise, they will have to price the products higher.

For instance, CM 1 manufactures towels that cost $1 to make. The MOQ set for the towels is 1,000 pieces. If you buy 5,000 towels, the price of the towels per piece is $2 only. The towels become $3 a piece if you buy the bare MOQ.

But you would not want to risk buying 5,000 towels because you are not sure if the towels will sell within a set timeline. So, you opt to buy the towels at a minimum.

Do you think the price is fair for your bottom line? If not, you can either negotiate or look for better options.

Does the contract manufacturer capable of meeting your quality standards? Can the contract manufacturer maintain the quality standards if you increase your sales demands? Does the contract manufacturer have the required manufacturing authorizations to operate?

These questions will help you choose a contract manufacturer who takes quality seriously. But go beyond asking.

All technology used in a product manufacturing facility should also have the necessary registrations and certifications to make sure the equipment is leveraged without errors.

All technology used in a product manufacturing facility should also have the necessary registrations and certifications to make sure the equipment is leveraged without errors.

If applicable, look for authorizations from Food and Drug Administration, Better Business Bureau, and other regulatory agencies. A raft of websites and digital resources are available for you to inspect reputation of contract manufacturing companies, from governmental to nonprofit websites that accommodate their legal and compliance histories.

Check if the product manufacturing company is ISO-certified to ensure that they have clean, safe, orderly, and well-maintained production facilities. If you are dealing with medical equipment, for example, all the more you will have to double check the machines. You cannot afford to risk precision.

The best way to assess the quality procedures of contract manufacturing companies is to personally perform a factory audit. A facility tour enables you to evaluate the skills of the production personnel and check the equipment.

Another transparent method to manage quality issues is to know if the contract manufacturing companies have a cloud-based quality control solution. It allows you to do an inspection on your products and gain insight into their processes without crossing borders.

The last thing you might want to do is to hire a sourcing agent who you can pay to inspect the quality of your products as they happen.

In addition, work with contract manufacturing companies that understand your business. It is important to check if the contract manufacturer has the experience in manufacturing products that are similar (or almost similar) to yours. Experience validates the legitimacy and capability of prospective contract manufacturing companies.

Do you think the contract manufacturer can scale up production themselves should you need it? Does the contract manufacturer have fluid resources and proactive production management capabilities?

Avoid contract manufacturing companies that have questionable resources. You do not want your company to drag on their inability to keep up with your demands, do you?

We have mentioned that experience matters when choosing a contract manufacturer. Gauge the short- and long-term practicality of an outsource contract manufacturer.

If you can see performance metrics (safety, cost, quality, and delivery) of contract manufacturing companies against industry standards, that should give you an idea of how these companies fared in the past.

Reputable contract manufacturing companies can deliver on your specified timeline and quality standards. In terms of deadlines, one of the dangers of contract manufacturing, however, is the lack of precedence.

Reputable contract manufacturing companies can deliver on your specified timeline and quality standards. In terms of deadlines, one of the dangers of contract manufacturing, however, is the lack of precedence.

If a contract manufacturer has multiple clients in a given industry, you need to ask for their turnaround system to make sure they meet your deadlines no matter how many clients will they serve.

As much as possible, do not operate on a first come, first served basis. Instead, ask the contract manufacturer if they have a sufficient amount of equipment and qualified workers to meet multiple clients at the same time.

Knowing that a contract manufacturer is in good financial shape is a must. Why is this so?

As a client company, you will be looking for possible disruptions in the course of the product manufacturing process during your risk assessment. Risk factors like natural disasters, raw material shortfalls, inventory mismanagement, market fluctuations, unrealistic expectations, equipment failure, subcontractor delays, and more are the real stress test in the product manufacturing industry.

Without a solid financial reserve, the chances of your product to be affected by these circumstances are so high. Worst case, a contract manufacturer goes out of business.

If you are outsourcing product manufacturing in China, knowing the location of your contract manufacturer can help you streamline your costs. Exported products from China have a value-added tax, and it varies by province.

Product manufacturing companies producing hi-tech items are usually located in Southern China while metal and other industrial items in the north.

A contract manufacturer that has value-added services is not always a necessity, but they may prove helpful to you in the grand scheme things. Expertise in planning support, market and demand forecasting, sophisticated reporting, and more is a huge advantage to be used as part of your contract.

Can the contract manufacturer test and pack your products? If you are in the dropshipping business model, dropshipping capabilities to send the product directly to customers is a good way to save lots of money.

On top of that, the contract manufacturer’s willingness and ability to modify their quality control systems and production process to meet your demands and requirements is something you would benefit in the long run.

Manufacturing overhead, also known as manufacturing support costs, factory overhead, factory burden, is the indirect costs incurred when a product is manufactured.

Manufacturing overhead expenses, together with direct labor and direct material, are normally assigned to each product or unit manufactured in order for the cost of goods sold and inventory are valued and reported to generally accepted accounting principles.

Manufacturing overhead may include factory utilities, depreciation of factory equipment and building, production personnel (other than direct labor), and production supplies. These factors and how they are imposed upon a product affect its profitability.

A profitable product should have a selling price greater than the sum of the product cost (direct material, direct labor, and manufacturing overhead), expenses, and nonmanufacturing costs or administrative overhead.

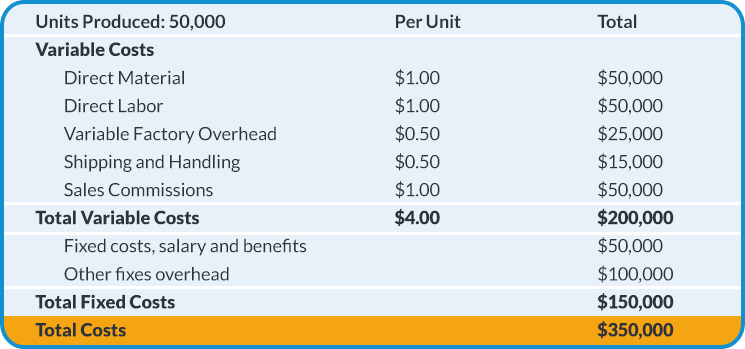

Here’s a hypothetical sample of manufacturing cost per unit of a towel when manufacturing the product on your own:

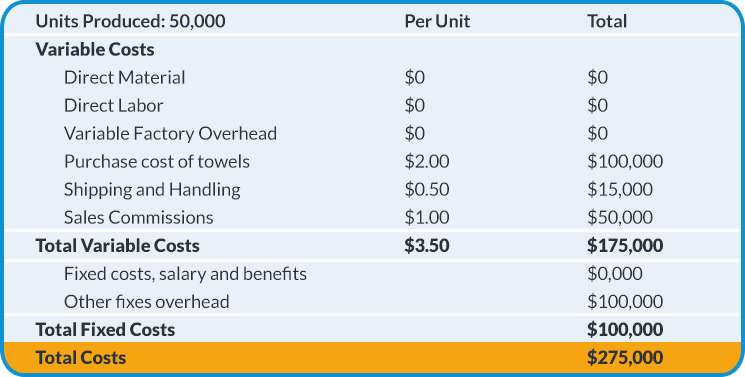

Here’s a hypothetical sample of manufacturing cost per unit of a towel when outsourcing the production to a contract manufacturer in China:

Direct material is the cost of all materials needed to manufacture a finished product, such as circuit boards, TV monitor, and anything that is integrated into a finished product. Indirect material refers to minor materials used in the production process, such as strands of wire, solder, etc. Indirect material is considered to be a manufacturing overhead.

Direct labor is the gross wage paid to all workers who physically and directly work on the manufacturing of the products. Indirect labor refers to the wages of other factory employees, such as supervisors, maintenance personnel, guards, etc. Indirect labor is considered to be a manufacturing overhead.

Manufacturing overhead is the total costs of manufacturing other than direct labor and direct material. Aside from indirect labor and indirect material, manufacturing overhead also includes utilities, maintenance, property taxes, insurance, repair, and factory-related depreciation.

Accountants refer prime costs to the components are direct in nature, that is, direct material and direct labor. Conversion costs are the components to transform raw materials to end products, that is, direct material and manufacturing overhead.

A request for quote (RFQ) is a standard process that companies use when preparing to buy products from a product manufacturing company. It is another important part of the process to avoid common pitfalls that you might experience when in the procurement stage.

We will walk you through the steps on how to request a quote from a supplier in China. As for the template, you can download free templates out there and modify them according to your needs.

Normally, a company creates and issues an RFQ to product manufacturing companies or contract manufacturing companies. The product manufacturing companies or contract manufacturing companies, in turn, offer price quotes.

The company selects the preferred contractor often based on the lowest bid or the contractor that can provide the best value for the buyer. A quote from product manufacturing or contract manufacturing companies is not final and cannot be used as a contract or formal agreement. Whatever is contained in the quote is subject to change.

There are different types of RFQ, namely:

Decide what requirements you would want to include in your RFQ. This will allow you to review bids in a well-organized manner. If you have a project manager or other relevant people in your organization, work with them to ensure you have included all the needed requirements.

The RFQ may include the following details:

At this point, you need to emphasize the type of bidding you intend to do. In your RFQ, include documents like a pricing template and draft contract with terms and conditions.

Once your RFQ is ready, distribute them to all candidate product manufacturing or contract manufacturing companies. Wait for them to respond with a quote.

You need to be ready to answer some questions regarding your RFQ. It is important to take note of them for future references.

To make sure you are transparent and fair in the bidding process, treat everyone equally with little to no preconceived ideas about them. Refrain from giving more information to select vendors over the others.

Once you have the quotes, acknowledge it and maintain the confidentiality if they are a sealed bid.

Review the quotes you received from the product manufacturing or contract manufacturing companies based on your selection criteria. Choose the winner with the lowest price at the best terms. Then, create a contract or purchase order to finalize the deal.

Do not forget to thank the product manufacturing or contract manufacturing companies who participated in the bid. Other concerns that you might raise with the winning vendor include packaging, delivery schedule, changes in pricing, etc.

Quality assurance (QA) and quality control (QC) should go hand in hand to prevent untoward circumstances during the product manufacturing process. Through quality assurance and quality control, your product is guaranteed to reach the hands of your consumers without defects.

Quality assurance (QA) and quality control (QC) should go hand in hand to prevent untoward circumstances during the product manufacturing process. Through quality assurance and quality control, your product is guaranteed to reach the hands of your consumers without defects.

Quality assurance is process-oriented, so it makes sure you are doing the right thing. Quality control, on the other hand, is product-oriented, so it tests the product quality.

From the selection of raw materials up to actual production, both principles are significant for the success of your product. Every step of the production process should have a set of procedures to monitor and control the progress. Here are some steps you can do.

First, evaluate the quality of technology, procedures and processes, and the labor of your contract manufacturer. This will allow you to detect, anticipate, and amend any quality and delivery issues.

If the contract manufacturer fails your quality standards, create testing methods with approved tolerance limits. If any event that the contract manufacturer goes beyond the set tolerance limits, you need to evaluate and address it.

To ensure product quality and lead time, most companies create a weighted decision matrix analysis to help you prioritize your needs and score each factor against your prerequisites. For example, your manufacturing decision should be based on cost, quality, time, and technology.

All product manufacturing or contract manufacturing companies have their own sets of strengths and weaknesses. By using a weighted decision matrix analysis, you can ensure the right company that can meet your standards and requirements.

Of course, nothing beats an on-site factory audit to ensure product quality. You can do regular factory checks, depending on your arrangement with your contract manufacturer. Audit reports should be compiled, including photos, videos, and timing updates, for references.

Intellectual property can be a source of competitive advantage. If you have a technology that is exclusive to you or a kind of product that has never been seen in the market yet, you should protect your intellectual property at all cost. But how would you do that?

People who have been in the product manufacturing business for quite some time know to protect one’s intellectual property or trade secrets from overseas contract manufacturers, protect them legally and operationally. No ifs and buts.

People who have been in the product manufacturing business for quite some time know to protect one’s intellectual property or trade secrets from overseas contract manufacturers, protect them legally and operationally. No ifs and buts.

One without the other does not guarantee you protection. A good contract and a good IP registration should go hand in hand to increase trust between you and a contract manufacturer.

Legally, companies who outsource manufacturing in China should make sure that they have all their legal documents prepared through patents and trademarks in both China and home country as well as supplier agreements like non-compete clause.

To protect your product early on, require the contract manufacturer in China to execute an appropriate agreement before giving out any information about your product. Use an NNN (non-disclosure, non-use, non-circumvention) agreement that is China-centric. Otherwise, it will not be valuable in China.

In order for the NNN agreement to be enforceable in a court in China, the exclusive jurisdiction is in a Chinese court with jurisdiction over the contract manufacturer, Chinese law is the governing law, and Chinese is the governing language.

On the operational side of things, use several anti-counterfeit technologies. If possible, operate in a way that even some of your intellectual property is stolen, all of it cannot be. For instance, keeping your software within your country. However, this is not foolproof at all.

On top of those, companies should be aggressive about monitoring the market for possible counterfeits of their technology, or regularly visit factories in China to reduce the risk of copied products. To monitor the market means attending trade fairs, scanning Alibaba and other online directories, and making mock purchase calls on your suppliers.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Product manufacturing, as you may have known by now, is not just about coming up with a final product or finding a supplier. It entails pretty complex processes from the ground up.

The new product introduction process in the beginning hugely helps in reducing cost brought by unforeseen revisions and design changes and in determining whether a product concept is marketable and/or saleable.

But as to manufacturing onshore or overseas, both have their own sets of advantages and disadvantages. Manufacturing products domestically is a great way to refine and protect your process and technology and take control over quality. Manufacturing products overseas, meanwhile, could very well help your overall profit margins and bottom line.

According to the Centre for Economics and Business Research (CEBR) forecasts, the Chinese economy will take over the United States as the world’s largest economy, and this can be directly attributed to China’s rapidly increasing output.

China currently has the world’s largest industrial output, which has been propelled by strong factory output, stable retail sales, and an export market that is constantly growing.

Outsourcing manufacturing in China means you get to take advantage of the highly skilled workers at a reasonable price, factories with stable facilities and advanced technologies at relatively low costs, and a better political stability.

In the following years, China will surely continue to be the center of product manufacturing industry, despite trade wars with the United States, emerging competition among developing countries, and the soaring labor and production costs, among other factors.

China Sourcelink is a leading supply chain solution provider that has base both in United States and China. We offer premium services in contract manufacturing, rapid prototyping, product design, product sourcing, quality control, and freight forwarding services for US companies that is planning to outsource manufacturing to China.

We are able to provide complete and tailor-made supply chain solutions for a wide range of industries, such as electronics and computers, hardware and tools, automotive, lighting equipment, building and construction material, machinery, textile and apparel, toys and consumer goods, packaging and more.

Shenzhen Office

Room 809 Building #1, 1026 Buji Road, Luohu, Shenzhen, Guangdong, China

Los Angeles Office

10501 Valley Blvd Suite 1800, El Monte, CA 91731, United States

Guangzhou Office

No.1304 Huizhou Building 313 of Huanshi Dong Road, YueXiu District, Guangzhou, China.

Hours of Operation

Monday-Friday: 9:00 am – 6:00 pm

Saturday: Closed

Sunday: Closed

Phone number and Email Adress

+8615889306565(China)

+12137162203(U.S.)

kai@cnsourcelink.com

How to manufacture a product: a comprehensive guide on finding contract manufacturing companies and outsourcing manufacturing to China.

The Complete Guide for Home Builders on Finding and Buying Wholesale Building Materials