China Sourcelink, we manufacture with quality and accuracy.

China Sourcelink provides metal fabrication services to create precision components for a range of industries and applications. Fabrication methods including cutting, drilling, CNC machining, punching, laser cutting, bending, welding, and sawing are utilized to produce customer specified parts. Typical lead times are 2 to 4 weeks, with medium to large volume production capabilities available. All products are manufactured at our ISO compliant facility, upholding the highest quality standards.

Here at China Sourcelink our custom laser cutting services offer customers a fast and efficient way to obtain precision cut metal shapes and blanks. Because no hard tooling is required, this process produces flat parts quickly and effectively. Parts can also be etched/engraved at the same time without costly secondary operations. Our expert machinists are able to handle all types of parts, from simple to complex, while meeting all your exacting specifications. Our 3-axis CO2 flying optics laser cutting system has a maximum power output of 2500 W. We can process hot rolled and cold rolled steel, aluminum and stainless steel up to 120” x 60”, in thicknesses up to 0.75”, with an accuracy of .004”.

Press brakes simplify the process of bending and forming sheet metal by clamping the metal between a punch and die. When looking for a press brake, there are several factors to consider including type, weight and thickness of the material. When typical dies are unable to make the required bends, due to unwieldy part size or depth, a variety of specialized dies, such as window dies can be used to overcome a range of similar challenges. Brake forming is a specialty at China Sourcelink. Hydraulic and mechanical presses allow fabrication of parts that are up to 30 ft long and 4 in. thick. Parts can be manufactured in steel, stainless, aluminum, abrasion-resistant AR400, and HSLA/Domex. Our CNC and forming fabrication are intended for applications that include angles, side frames, rails, and crane booms.

Utilizing state of the art metal stamping equipment and quality control system, China Sourcelink continues to provide superior parts and excellent customer service to the electrical, bearing, janitorial, heavy equipment and construction (commercial & residential) sectors, just to name a few. Our metal stamping services encompass many processes; these include progressive die stamping, coining or shallow draw stamping, blanking, piercing, laser cutting, bending, and forming. These processes and our manufacturing operation are designed for the forming of a wide range of materials.

China Sourcelink offers precision CNC punching services, for the high-speed fabrication of custom parts. This process is ideal for parts specifying multiple precision holes, including perforated hole patterns and countersunk hole detailing. Our advanced CNC controlled turret press equipment with 33 tons of punching force can handle mild steel, stainless steel, aluminum, brass and copper in sheet sizes up to 4′ x 10′ and material thicknesses ranging from .024″ to .25″ thick. Our process holds tolerances of ± 0.005″

China Sourelink boasts a broad range of plate, angle and sheet metal rolling capabilities. With a number of CNC as well as manual rolls there we are well equipped to take on most rolling jobs. With expert operators we can roll both thin gauge sheet metal as well as heavy plate to exact tolerances. We typically roll aluminum, stainless steel, carbon steel, cor-ten and other materials on our plate roll. We have a perfect line up of metal rolling machines with plate rolls, angle rolls, and profile tube benders that deliver reliable performance you can count on.

Metal shearing is an effective way of separating metal into two parts without using any form of heat. The term “shearing” by itself refers to a precise cutting method that produces straight line cuts to separate a piece of sheet metal. The operated shear machine applies a large amount of force to cut the metal accurately and precisely. Commonly used materials for this process include stainless steel, aluminum, cold rolled steel, bronze, brass and copper.

Many metal manufacturing companies overlook the art of saw cutting. However, precision saw cutting is an essential procedure in many metal fabrication projects that can also be useful when manufacturing products made from various types of plastic material. Trusting this important procedure to an experienced metal company can lead to unsatisfactory results and negatively impact the quality and performance of your products. At China Sourcelink, quality and precise equipment, as well as experienced professionals, produce the highest quality cut products. Our saws are suited for high volume, repeating applications with excellent reliability. Precision saw cutting is used to supply gram weight tolerance, precision-cut parts that are ready for a forging machine or machining center.

Welding is the process of permanently joining two or more metal parts, by melting both materials. The molten materials quickly cool, and the two metals are permanently bonded. China Sourcelink has decades of complex welding experience. Our skilled welding staff provides a full range of welding services. We can provide welding services ranging from structural and plate welding to light gauge tubular steels, stainless, and aluminum for both Metal Inert Gas (MIG) welding and Tungsten Inert Gas (TIG) welding. Our skilled MIG and TIG welders are AWS certified, and also trained to read engineered plans and make high-quality parts to spec. Our welding equipment is precisely calibrated semi-annually for quality assurance.

China Sourcelink offers custom sheet metal fabrication services that enhance and supplement our precision metal stamping capabilities. Our extensive knowledge and experience in all aspects of metal working enable us to provide you with products and services that are of the highest in the industry.

Our unique sheet metal fabrications feature the consistency and durability required of components incorporated into modern industrial and consumer equipment. From prototype to production, our state-of-the-art equipment can handle precise specifications and demanding tolerances to produce machined components that meet required accuracy and consistency criteria of precision applications.

We accept and work from virtually any type of electronic file and our capabilities allow us to work with a wide variety of materials. It is our flexibility, adaptability, and metal forming expertise that enables us to supply many diverse components to many different industries. With an outstanding range of capabilities, we are able to fabricate parts of all shapes and sizes. Examples of our sheet metal fabrications include chassis, metal cabinets, and countless other flat and formed sheet metal parts.

We have the capability of running rapid prototypes to large production quantities and contract manufacturing. In response to industry demands we have been able to streamline our operations creating shorter lead times for our customers.

Contract Manufacturing

Component Manufacturing

Secondary Operations

Progressive Metal Stamping

Tool and Die Design

Value-Added Engineering Services

Prototyping

Medium to High Volume Production

Aluminum

Brass

Bronze

Cast Iron

Cold Rolled Steel

Copper

Hot Rolled Steel

Plastics

Stainless Steel

Tubing

Aggregate

Agricultural

Alternative Energy

Automotive

Concrete

Construction

Electronics and Computer

Food Processing

Health & Fitness

Industrial Manufacturing

Petro Chemical

Telecommunications

Transportation

Specialized Fabrication Products

Tanks

Columns

Conveyors

Cones

Elbows

Channels

Buckets Cylinders

Tooling

Base Plates

Wind Load Stiffeners

Angle Clips

Material Handling Equipment

Laser Cutting

Press Brake Forming

Metal Stamping

Punching

Rolling

Shearing

Saw Cutting

Welding And Assembly

Painting

Galvanizing

Plating

Powder Coating

Heat treating

Threading

ISO 9001:2008

AWS D1.1, D1.2 & D1.3 Welding

CWI (Certified Welding Inspector)

Statistical Process Control (SPC)

Just In Time (JIT) Compliant Delivery

Member AWS, AME, SAE, FMA

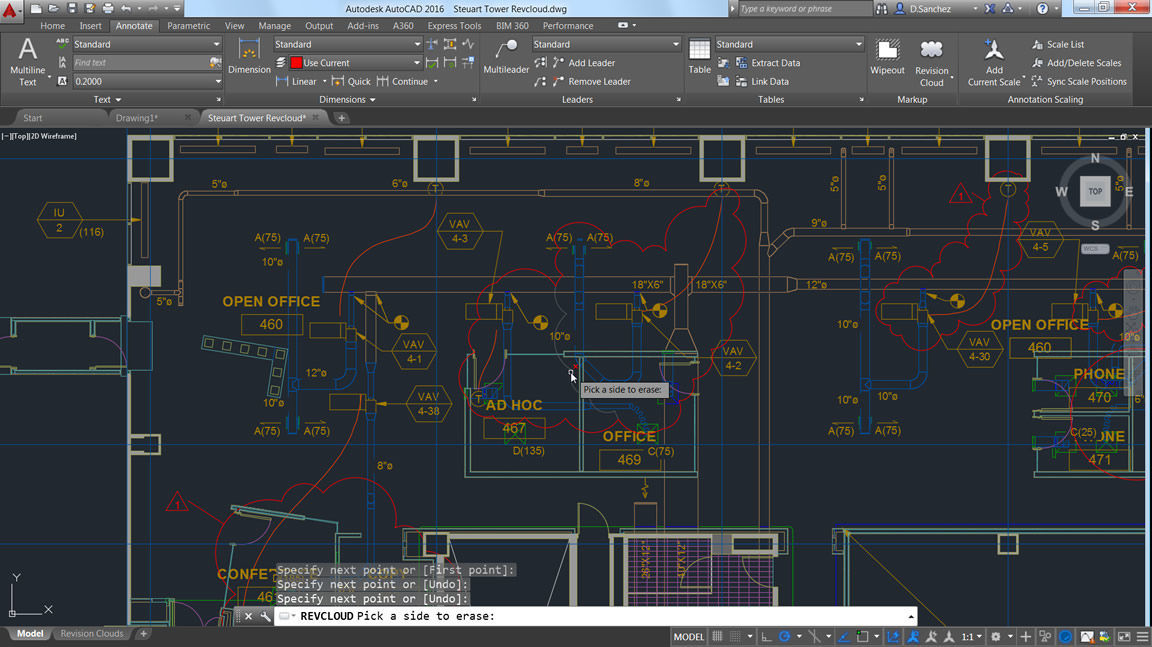

AutoCAD (DWG, DWZ)

BMP (Bit Mapped Graphics)

DXF (Drawing Interchange Format, or Drawing Exchange Format)

GIF (Graphics Interchange Format)

IGES (Initial Graphics Exchange Specification, ANSI File Format)

Inventor (IDW, IPT)

JPG or JEPG (Joint Photographic Experts Group)

PDF (Portable Document Format)

Pro-E or Pro/Engineer (DRW, PRT, XPR)

SAT (3D ACIS Model File)

SolidWorks (SLDPRT, SLDDRW, SLDDRT)

STEP (Standard for the Exchange of Product Model Data)

TIFF (Tagged Image File Format)

We manufacture metal product with quality and accuracy.

China Sourcelink is a leading supply chain solution provider that has base both in United States and China. We offer premium services in contract manufacturing, rapid prototyping, product design, product sourcing, quality control, and freight forwarding services for US companies that is planning to outsource manufacturing to China.

We are able to provide complete and tailor-made supply chain solutions for a wide range of industries, such as electronics and computers, hardware and tools, automotive, lighting equipment, building and construction material, machinery, textile and apparel, toys and consumer goods, packaging and more.

Shenzhen Office

Room 809 Building #1, 1026 Buji Road, Luohu, Shenzhen, Guangdong, China

Los Angeles Office

10501 Valley Blvd Suite 1800, El Monte, CA 91731, United States

Guangzhou Office

No.1304 Huizhou Building 313 of Huanshi Dong Road, YueXiu District, Guangzhou, China.

Hours of Operation

Monday-Friday: 9:00 am – 6:00 pm

Saturday: Closed

Sunday: Closed

Phone number and Email Adress

+8615889306565(China)

+12137162203(U.S.)

kai@cnsourcelink.com

How to manufacture a product: a comprehensive guide on finding contract manufacturing companies and outsourcing manufacturing to China.

The Complete Guide for Home Builders on Finding and Buying Wholesale Building Materials