No worries. Let me send you a copy so you can read it when it’s convenient for you. Just let me know where to send it (takes 5 seconds):

As the global metal fabrication market continues to experience exponential growth in the past couple of years, demand for steel, aluminum, and other metal products in major industries are also expected to increase. China has been leading the world’s steel manufacturing industry with demands coming from industries like aircraft, automotive, and construction.

Many of China’s importers come from the U.S. Industry-leading metal fabrication shops and companies like Ball Corporation, Flowserve Corporation, Gibraltar Industries, Mueller Industries, The Timken Company, and Valmont Industries all have manufacturing arms in China.

Formed by about 51,000 companies, the fabricated metal product manufacturing industry in the U.S. has about $338 billion in combined annual revenue last year. Companies in the U.S. and the rest of the world are expected to take advantage of China’s metal fabrication capabilities, skilled labor force, and favorable production costs moving forward.

What Is Metal Fabrication?

What Is Metal Fabrication?Metal fabrication is the creation of metal parts, structures, and machines from various raw materials by cutting, bending, and assembling process.

Metal fabrication is a crucial step in the manufacturing process. However, it is often a misunderstood trade. Most people think it is the same as welding fabrication, which is only one of the many methods fabrication shops use.

Most mass-produced fabricated metal items like cans, pipes, bolts, and cutlery have a wider tolerance for error. This means each product may vary in minute details from the original design but still acceptable and functional. On the one hand, there is the so-called custom metal fabrication sector where businesses specialize in custom products to fit a customer’s specifications.

Sheet metal fabrication uses sheet metal to build structures and machines. Businesses specializing in sheet metal fabrication are often called fabrication shops, or fab shops for short. Some tools used in sheet metal fabrication may include a rolling machine, plasma machine, band saw, hydraulic brake, and sandblasting machine, among many others.

Precision sheet metal fabrication is the process of forming sheet metals into finished products. Medical, aerospace, automobile, electronics, and military industries all depend on precision sheet metal fabrication. Precision sheet metal fabrication relies heavily on computer technology to get the desired results, particularly CAD/CAM software to design and layout products and CNC machine to cut, drill, or lathe products to exact specifications.

Precision sheet metal fabrication subjects a sheet metal into annealing, bending, mechanical working, press forming, or roll forming to create the desired shape. To make that into a finished product, the shaped sheet metal goes through cutting, drilling, sawing, shearing, or stamping to achieve the finished product. Finishing processes of precision sheet metal fabrication include deburring, painting the product, or sanding. Some of the most common products of precision sheet metal fabrication include storage enclosures, mobile carts, tanks, and ventilation systems.

Sheet Metal Ductwork Fabrication

Sheet Metal Ductwork FabricationSheet metal ductwork fabrication involves building ducts, usually for HVAC systems. Some tools to create sheet metal ducts include a plasma machine, lock former machine, hydraulic notching machine, power break machine, hand brake machine, and cleat former machine. Products of sheet metal ductwork fabrication include plenum boxes, drain pans, duct mate, straight ducts, grease ducts, and trunk ducts.

HVAC sheet metal fabrication is a subcategory of precision sheet metal fabrication. It is imperative to meet all industry standards, particularly for industry ductwork. This is because ductwork may carry huge amounts of boiling or dusty air throughout the HVAC system. This air may reach temperatures as high as 1,000 degrees Fahrenheit (515 degrees Celsius). Having quality ductwork ensures that the air reaches its destination in the safest way possible.

Sheet metal duct fabrication for indoor air distribution use varying gauges. But mostly they are rectangular or circular in shape.

Trunk ducts carry the conditioned air from the air handler out to the plenum from which branch ducts distribute to individual air distribution outlets. The sheet metal thickness for trunk ducts varies in gauges, either 26, 28, or 30.

Plenum ducts serve as a collector box that is directly attached to the supply outlet of an HVAC system. Plenum ducts vary in sizes.

Overall, sheet metal ducts usually come in 3-feet lengths for easy handling. One end of each piece is crimped to fit well with consecutive joints. The seams are mostly formed on a snap-lock machine to make it easy to assemble.

Custom metal fabrication often involves stock metal components, such as sheet metal, metal bars, metal billets, and metal rods, to create a new product. For instance, a metal billet may be fabricated into a curve metal tube by using extrusion and folding the tube.

Some of the most popular types of metal used in custom metal fabrication include steel, aluminum, brass, copper, and titanium. Depending on the product’s intended purpose, geometry, and materials, the custom metal fabrication process may include casting, cutting, folding, extrusion, forging, punching, machining, shearing, drawing, stamping, or welding.

Custom Sheet Metal Fabrication

Custom Sheet Metal FabricationBefore a finished custom sheet metal fabrication product is handed over to the customer, it has to go through a series of sheet metal fabrication processes and tools, depending on the application it serves. The goal is to convert a metal sheet into a workable item.

The custom sheet metal fabrication process includes blanking, bending and forming, assembly, or finishing. Some tools used in custom sheet metal fabrication include a turret press, water jet cutting machine, folding machines, press brakes, stamping units, and fiber optic laser cutting machine.

Metal fabrication is too broad of a term that refers to any process involving cutting, shaping, and molding. There are so many processes involved in metal fabrication, and they vary in mechanism and tools to use.

But, at the end of the goal, the goal is the same—to produce parts or assemble components to make a finished product. To learn more about the processes in metal fabrication, here are 12 of the most common techniques used to fabricate a metal product.

Metal Cutting

Metal CuttingCutting is the most common metal fabrication process where sheets of metal are cut into smaller parts. In most applications, the metal being cut is freshly manufactured and has yet to be made into anything in particular. In other applications, pre-shaped metals like panels and bars are subjected to cutting. Some cutting machines include lasers and plasma torches, power scissors, waterjet cutting machines, and CNC machines, among others.

Metal Drawing

Metal DrawingDrawing requires tensile force to pull metal into and through a tapered die. The die expands the metals into a thinner shape. The drawn metal can be heated to lessen the required force. The process is called deep drawing when the finished product has a depth that is equal to or greater than its radius. For instance, hollow cylindrical or box-shaped vessels drawn from a sheet of metal.

Forging employs compressive force to shape metal and often achieved using a hammer or die. Forging is one of the oldest forms of metal fabrication which has been used for centuries. Metal forging can either be done at room temperature (cold forging), above room temperature to below the recrystallization temperature (warm forging) or above recrystallization temperature (hot forging).

Metal Folding

Metal FoldingFolding is a complicated metal fabrication process whereby the metal surface is manipulated to bend at a certain angle using folding. It can be done using a brake press, hammer, or the folder machine.

Welding fabrication is another popular metal fabrication techniques. This process involves joining or cutting two metal parts using a welding machine. The metal parts could be metal sheets, panels, bars, or whatnots.

Metal Extrusion

Metal ExtrusionExtrusion uses force through and around an open or closed die to reduce the diameter of the metal piece to the cross-section of the die. When pressed around a die, the metal piece gets a cavity within. Extrusion uses a metal slug (billet) as the workpiece and a ram to strike it. The finished product is often used for wiring or piping. It can be long or short pieces.

Cold extrusion is done at room temperature, and it is often used for steel fabrication, including stainless steel fabrication. On the other hand, hot extrusion is done at high room temperature to prevent the metal from hardening. Hot extrusion is often used for copper fabrication.

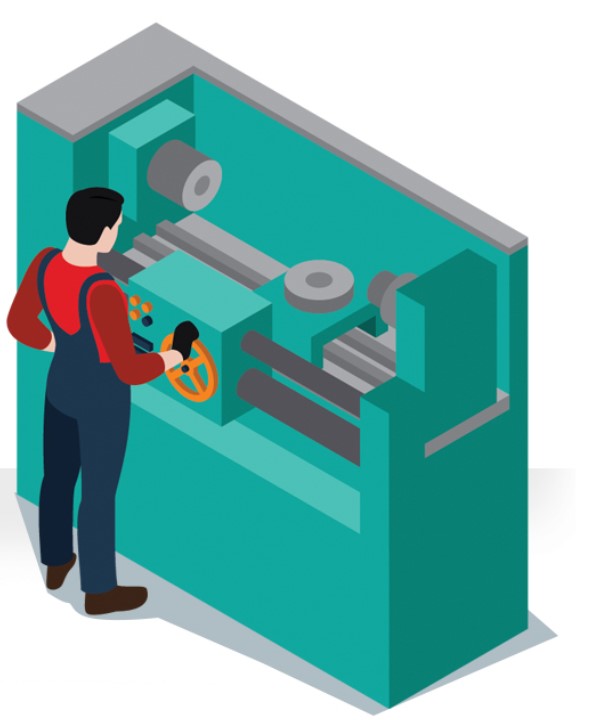

Metal Machining

Metal MachiningMachining is used to remove parts from a piece of metal. It is usually performed on a lathe. In other machining applications, a hole or set of holes are formed directly through the metal surface.

Machining can be done by drilling, turning, and milling. Drilling uses a rotary cutting tool called drill bit to punch a hole. Turning uses a lathe to rotate the metal while a cutting tool moves in a linear motion to remove metal along the diameter, making a cylindrical shape. Lastly, milling uses rotating multi-point cutting tools to remove materials from the workpiece until the desired shape is achieved.

Metal Punching

Metal PunchingPunching creates holes in a workpiece by placing it under a die and punching it through using a drill. A CNC punch press is a common tool used here.

Shearing involves long cuts. In most applications, the sheet is loaded through a metal-cutting machine. In other applications, the sheet is cut using a cutting tool. Shearing is often applied to trim down the edges of a metal sheet.

Metal Stamping

Metal StampingStamping is the process of making tiny humps protruding on the metal sheet. Like punching, it uses a die, except that the punching process does not penetrate to avoid making a hole. Metal stamping is often seen on coins.

Casting is another ancient process of metal fabrication. It involves molten metal poured into a mold to form something. The most common metals used in casting include steel, iron, gold, copper, silver, and magnesium.

Techniques for metal fabrication vary in complexity with respect to the desired qualities of the finished product and the composition of the materials in use. Hardness, strength, conductivity, and resistance to corrosion are all commonly sought after qualities.

Techniques for metal fabrication vary in complexity with respect to the desired qualities of the finished product and the composition of the materials in use. Hardness, strength, conductivity, and resistance to corrosion are all commonly sought after qualities.

Through different methods in cutting, bending, and welding, these metals can be used in a multitude of products ranging from toys and appliances to larger structures like ductwork, furnaces, and heavy machinery.

In this section, let us explore the different types of metal fabrication according to the materials used, including steel fabrication and aluminum fabrication.

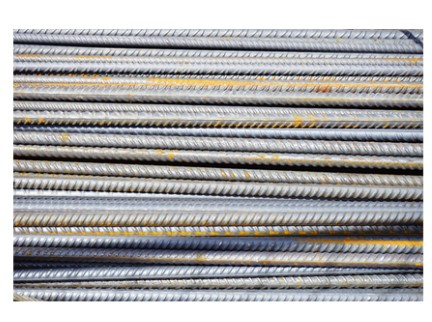

Steel Fabrication

Steel FabricationSteel fabrication involves the use of steel—an alloy of iron and carbon—and is the most common material used in metal fabrication. Its endless range of products includes construction materials, weaponry, and machinery.

Steel is most difficult to cut and so it requires a fairly extensive fabrication process. It is likely to corrode and can withstand 400 degrees Fahrenheit or more.

Steel fabrication has a lot of types according to the purpose. It could be structural steel fabrication, custom steel fabrication, custom stainless steel fabrication, commercial steel fabrication, and industrial steel fabrication.

![]()

Stainless steel fabrication involves carbon steel, aluminum, chromium, and other elements that combine to create a metal that is highly resistant to corrosion. Products of stainless steel fabrication are popular because of their polished silver mirror coating. Additionally, stainless steel does not tarnish in air. Some products of stainless steel fabrication are cookware, surgical instruments, appliances, cabinet fittings, and metal ceramics.

![]()

Custom steel fabrication products undergo a series of steel fabrication processes and tools for the purpose of making steel fabricated products into a functional item. The custom steel fabrication process may include bending, forming, assembly, blanking, or finishing.

![]()

Custom stainless steel fabrication is made of stainless steel fabrication products to create custom stainless steel fabrication products like water bottles, countertops, grill gates, backsplash, and straws, among others.

Structural steel fabrication produces steel used for making construction materials in a variety of shapes. Many products of structural steel fabrication take the form of an elongated beam.

![]()

Products of commercial steel fabrication are used for residential and commercial buildings. Commercial steel is mild steel that has a PSI of around 40,000 only. It is soft, lightweight, and malleable so it is easy to weld. Commercial steel, nevertheless, is strong enough for various commercial applications.

![]()

On the other hand, products of industrial steel fabrication are twice as strong as commercial steel fabrication products. They are used in structures that are designed to withstand heat and other environmental factors. Of course, they are thicker, heavier, and more expensive than products of commercial steel fabrication.

Aluminum Fabrication

Aluminum FabricationProducts of aluminum fabrication are best used for low-temperature applications like refrigeration and aeronautics. As you may know, aluminum is lightweight and durable with great thermal and electrical conductivity. It performs well both at temperatures higher than 400 degrees Fahrenheit and temperatures below zero. Aluminum fabrication products may not be as strong as stainless steel, but they are versatile and more affordable.

Custom aluminum fabrication may involve different process depending on the purpose, such as shearing, CNC machining, punching, bending, laser cutting, welding, extrusion, and assembling. Different finishes can also be applied like a mill, anodization, powder coating.

Here are some products of custom aluminum fabrication:

BBC fabricated aluminum valve covers for Chevrolet’s Big-Block engines that vary in height.

Custom aluminum boat fabrication can do sports custom built aluminum boats, from sports boats to rib boats to crew boats to pleasure craft. Products of custom aluminum boat fabrication may also include fuel tanks, water tanks, and metal parts for boats.

The demand for products of aluminum windows fabrication is growing in construction industries. More and more homes and commercial spaces are now using aluminum windows rather than wooden ones because they are more affordable.

Custom aluminum wheel fabrication is another niche that will go nowhere in the future as the demand for vehicles keeps on growing. Many aluminum fabrication shops do custom wheel designs for almost every taste.

<h4id=”chapter3215″>Custom Aluminum Dash Fabrication

Custom aluminum dash fabrication is a developing business. Aluminum dashes, door panels, and skins under fiberglass bodywork on tube gram vehicles are picking up fast.

Aluminum Composite Panel Fabrication

Aluminum Composite Panel FabricationProducts of aluminum composite panel fabrication are perfect for exterior cladding systems, or the facade of buildings used to protect them against the weather while still giving a really attractive look. Aluminum composite panels can also be used for interior design.

Aluminum Fabrication Kitchen Products

Aluminum Fabrication Kitchen ProductsAluminum fabrication kitchen products include cabinets, cookware, utensils, shelves, and countertops, among many others.

Many aluminum motorcycle tank fabrication shops offer custom gas tanks to improve the silhouette and style of a motorcycle. These fabrication shops also produce aluminum gas tank filler necks and other products that will make gas tanks really good.

Aluminum radiator fabrication parts are used in cars, motorcycles, aircraft, and HVAC system. Many aluminum fabrication shops offer custom and stock products for radiators.

Aluminum fan shroud fabrication shops can make custom aluminum fan shroud to fit radiators. These custom fan shrouds can be fabricated for use with electric cooling fans and even low profile electric fans.

Steel and aluminum may be the most common metals used in most fabrication jobs, there are also other materials that are utilized in other industries, including titanium, copper, bronze, and brass.

Titanium has a strong density and structure. That’s it’s used in the military aerospace industry. Today, titanium fabricated products are now being used in marine, industrial, chemical processing, consumer, medical, and sporting goods. Titanium fabrication products include press vessels, pipes, and mills, among many others.

![]()

Titanium pressure vessels are used to contain gases or liquids at high pressures. Using titanium, it reduces danger and fatal accidents.

![]()

Pipe fabrication involves welding of components like pipes, elbows, flanges, and tees, into piping systems.

Copper fabricated products are useful in marine and industrial environments. Copper is a perfect conductor of electricity. It’s tough, malleable, ductile and resistant to corrosion.

Copper roofing offers character and durability that no other metal roofs can match. It’s long-lasting and cost-effective.

Bronze is a copper alloy but stronger than copper and heavier than steel. Bronze fabricated products have a low melting point, so they are often used to manufacture coins, weapons, armor, cookware, and turbines.

Brass is an alloy composed of zinc and copper. Some brass metal fabricated products include nuts, bolts, strips, pipe fitting, bed frames, door knobs, detectors, furniture trim, clock components, and musical instruments.

![]()

Brass metal sheets and plates are used in manufacturing, construction, electrical, and plumbing industries to create gears, bearings, nuts, bolts and threads, and valves and ammunition casings, among others.

![]()

Brass metal strips are often used for doors, inlay, flooring, furniture, and tile. They are also used as decorative pieces.

![]()

Brass metal bed frames are not as common as steel metal. However, brass metal bed frames are valued for their high strength and machinability.

The manufacturing industry could go down as the biggest source of revenue for the metal fabrication industry. It could be subdivided into architectural and structural metals manufacturing, shipping manufacturing, spring and wire product manufacturing, specialty manufacturing, hardware manufacturing, cutlery and hand tool manufacturing, and machine shop manufacturing. Almost every industry that requires manufacturing of metal products relies on metal fabrication.

The building and construction sector is another contributor to the metal fabrication industry. Most architects and engineers prefer using fabricated steel products for buildings, bridges, warehouses, and all kinds of megastructures. At present, it is close to impossible to think of the construction industry without metal fabrication.

Aerospace engineering involves producing and designing all kinds of aircraft such as commercial aircraft to defense aircraft. These giant vehicles are made possible using metal fabrication products at every stage of production.

The automotive industry uses metal fabrication in order to make pieces to build automobiles. The tools used in the assembly process also relies solely on metal fabrication.

The transportation industry needs intricate parts for trains, buses, ships, and every kind of transportation imaginable. It needs precise sheet metal fabrication to function properly.

Of course, there are countless industries relying on metal fabrication. Other industrial sectors needing the help of metal fabrication include energy, mining, medical, among many others.

Metal fabricated products can be easily categorized into three: commercial, industrial, and structural. Although we have covered this in the previous section, we will delve into more examples of metal fabricated products by categories.

Commercial fabricated products cover goods designed for use by consumers. Here are some good commercial fabricated products:

Industrial fabricated products create pieces to be used in other equipment. This equipment is then used to manufacture consumer goods. Here are some good industrial fabricated products:

Structural fabricated products are the result of metalworking done as part of the building process. Here are some good structural fabricated products:

Depending on the purpose of metal fabrication, each process may need different equipment. Some metal fabrication equipment, though, can be used for a variety of functions, including welding machines, CNC machines, and saws.

A good fabrication shop, however, does not need all the metal fabrication tools in the world to successfully operate. It all boils down to specializations to know which machine is a must-have.

Here are some pieces of equipment used in metal fabrication:

Laser cutting machines are used to lessen the mechanical stress a sheet metal form experiences while being cut. Laser cutting machines can produce sheet metal tags, engraved sheet metal, cut sheet metal baskets, and cut-out parts, among many others. Top-notch laser cutting and engraving machines in the United States from industry leaders include:

A press brake machine is used to bend or fold structural steel plates and sheets by clamping them between a matching punch and die pair. It is used to make steel sheets and strips into sections, angles, channels, and girders. Press brake machines offer accuracy and versatility for bending simple or complex metal parts. Some of the best press brake manufacturers in the United States include:

An ironworker is the most versatile metal fabrication tool of a machine shop. It can be for punching, notching, and shearing, among other functions. It saves time, effort, and cost. If you are hunting for ironworkers, you can find quality models like:

Swing beam shears are used particularly for cutting structural steel. Shears are a cost-effective cutting solution because they are quick to set up and easy to use. Some of the best manufacturers of swing beam shears are:

Plate rolls are designed to transform flat sheet metal into cylindrical or radius parts in a fast and efficient manner. They are available in a variety of roll diameters and lengths. Plate rolls are suitable for medium and thick plate bending. Some of the best plate rolling and bending machines are:

Choosing between a local metal fabricator and a metal fabricator in China is not easy. Each camp has its own set of advantages and disadvantages. At the end of the day, it all boils down to your personal requirements and preferences.

However, you need to take into account that mistakes can really be expensive in this industry. To help you decide, let’s look at local metal fabrication companies in Los Angeles and the United States as well as metal fabrication companies in China.

Finding local metal fabrication companies in Los Angeles is not as hard because there are a lot of them. Choose a local fabrication shop in Los Angeles to:

On the other hand, there are reasons why a lot of companies in the United States are outsourcing their metal fabrication needs from China. Choose a metal fabrication company in China if you need:

When choosing the right metal fabrication company, you need to look at factors like:

But, it’s not fair to say that metal fabricators in China are better on all counts than metal fabricators in Los Angeles and vice versa. You need to look at the individual capabilities of a metal fabrication company before deciding.

But, if you really want to be smart with your choices, the best decision would be to work with a local metal fabricator that has offshore capabilities in China. That way, you will save up manufacturing overhead by outsourcing the labor-intense part to a Chinese metal fabricator.

China Sourcelink is the industry-leading metal fabrication provider of precision components for various industries and applications. We offer metal fabrication services like cutting, drilling, CNC machining, punching, laser cutting, bending, welding, and sawing. We are based in Los Angeles with offshore capabilities in Shenzhen, China.

We can handle medium to large volume production requirements with a fast turnaround time of 2 to 4 weeks. Our facility in Shenzhen is ISO compliant so you can rest assured we fabricate metal products at the highest quality standard.

Our turn-key metal fabrication services include:

To walk you through our metal fabrication process, let us show you an example of how we fabricate a metal product in the form of steel frames and accessories.

| Quantity (in meters) | Price Per Meter (in USD) |

| Less than 100 | $5 |

| 100 – 499 | $.3 |

| 500 or more | $.1 |

| Quantity (in meters) | Price Per Ton (in USD) |

| Less than 1 | $750 |

| 1 – 4 | $680 |

| 5 or more | $650 |

| Quantity (in pieces) | Price Per Piece (in USD) |

| Less than 100 | $.20 |

| 100 – 499 | $.10 |

| 500 or more | $.05 |

This is for sample purposes only.

For inquiries on pricing and customized options, contact China Sourcelink at +1 213 716 2203 (U.S.) or +8 615 889 3065 65 (China) or kai@cnsourcelink.com

You have finally reached the end of our metal fabrication guide. We hope you have learned more about the different processes, materials, industries, and products that are all related to metal fabrication.

Before ending this article, we have a few key takeaways that we hope you are going to bring with you after this.

China Sourcelink is a metal fabrication company based in Los Angeles, California with offshore contract manufacturing capabilities in China.

We are happy to serve your metal fabrication needs in Los Angeles, California and the surrounding areas:

Orange County | San Diego | Riverside | San Fernando Valley | Burbank | Southern California | California | Bay Area

Take care of your business, and we will take care of your outsourcing!

Call us at +1 213 716 2203 (U.S.) or +86 15889306565 (China).

Visit our Los Angeles office at 177 E Colorado Blvd, Pasadena, California.

China Sourcelink is a leading supply chain solution provider that has base both in United States and China. We offer premium services in contract manufacturing, rapid prototyping, product design, product sourcing, quality control, and freight forwarding services for US companies that is planning to outsource manufacturing to China.

We are able to provide complete and tailor-made supply chain solutions for a wide range of industries, such as electronics and computers, hardware and tools, automotive, lighting equipment, building and construction material, machinery, textile and apparel, toys and consumer goods, packaging and more.

Shenzhen Office

Room 809 Building #1, 1026 Buji Road, Luohu, Shenzhen, Guangdong, China

Los Angeles Office

10501 Valley Blvd Suite 1800, El Monte, CA 91731, United States

Guangzhou Office

No.1304 Huizhou Building 313 of Huanshi Dong Road, YueXiu District, Guangzhou, China.

Hours of Operation

Monday-Friday: 9:00 am – 6:00 pm

Saturday: Closed

Sunday: Closed

Phone number and Email Adress

+8615889306565(China)

+12137162203(U.S.)

kai@cnsourcelink.com

How to manufacture a product: a comprehensive guide on finding contract manufacturing companies and outsourcing manufacturing to China.

The Complete Guide for Home Builders on Finding and Buying Wholesale Building Materials