Pros:

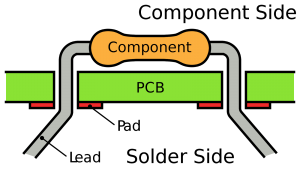

Thru-Hole Device(THD) soldering provides stronger mechanical bonds than any other PCBA technique.

THD soldering is the optimal PCBA technique for connectors, transformers, electrolytic capacitors, and other heftier circuit board components.

THD soldering is considered to be the go-to process over SMT for many military or aerospace products.

Cons:

THD soldering requires drilling into the bare board, which makes it a more time consuming process than SMT.

THD soldering is more expensive than using SMT.

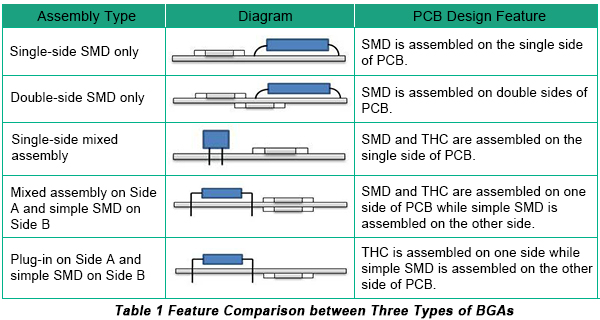

THD mounting may not allow for as high a component density as SMT does.

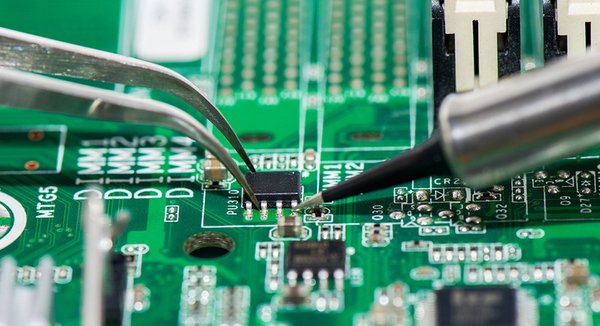

THD mounting often requires hand-soldering, which is considered to be less reliable than the reflow ovens used in surface mount PCBA.